Heating from a garage furnace is an excellent solution for expanding your living or working area during the cold months of the year. Turn your garage into a heated workshop, family play area or game day hangout.

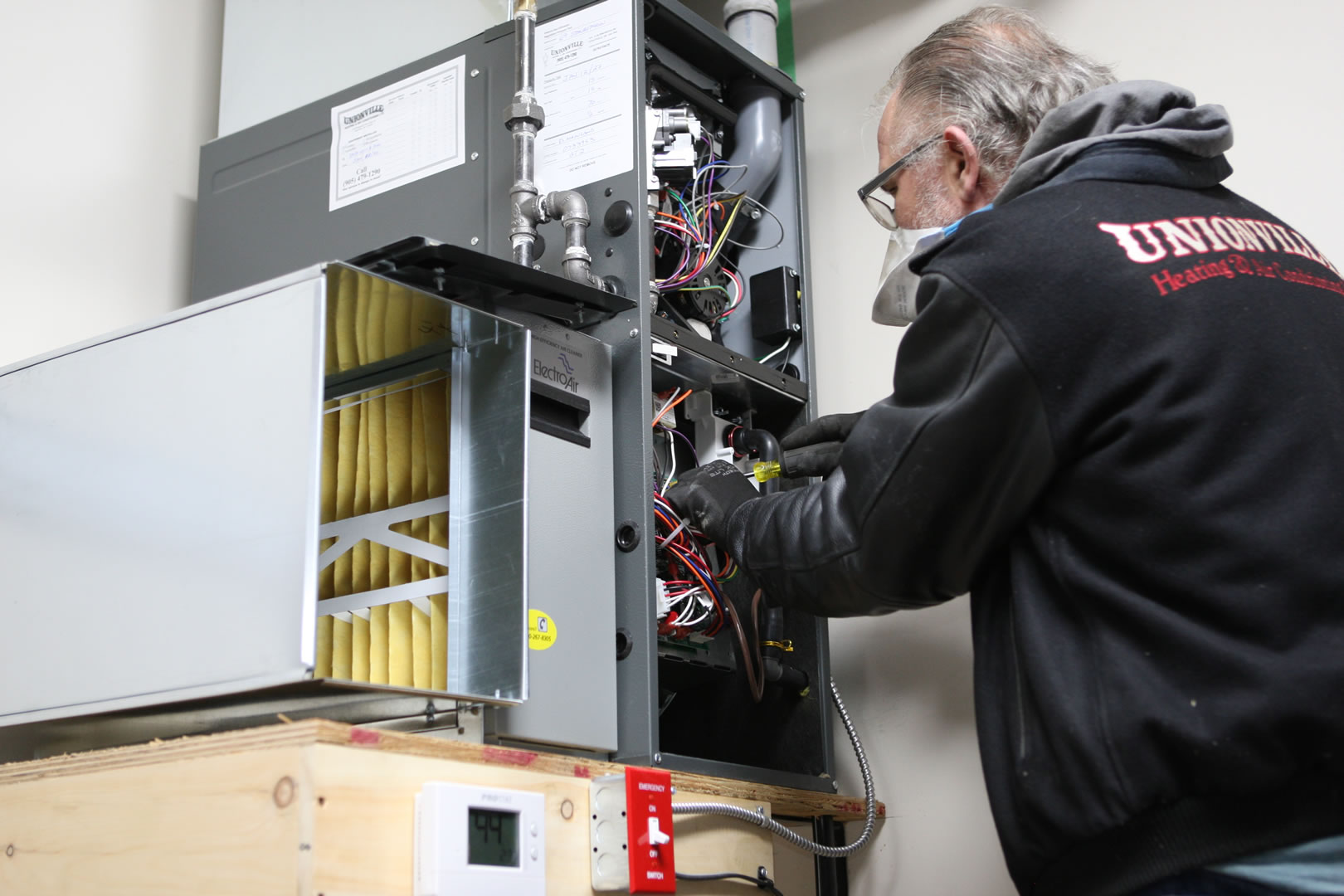

A licensed HVAC contractor performs this How-To guide.

The gas furnace we chose is 96% efficient. That means of all the gas you buy to heat the space, only 4% will be expelled with the exhaust.

The Installation Manager visits the job site before the install date to consult on location and measurements for furnace placement and electrical and gas connection locations. The unit must have a dedicated circuit for power. The gas line is a continuous one-piece connection from the gas source to the furnace.

Click here to get a Quote for a garage heater installation in York or Durham Region.